Classic copper cables reach their limits in the multi-gigabit range

The demands for data transmission in modern vehicles are increasing rapidly, but “information highways” are still based on traditional technologies. Classic copper cables reach their limits due to material and technology, which raises an important question: Is it time to switch to a new transmission technology? Optical data transmission could be the solution. Learn how this technology has developed, what advantages it brings and why it is increasingly becoming the focus of the automotive industry.

Why wasn’t optical data transmission adopted in the automotive industry long ago?

Optical data transmission commands a global presence: Since fiber optics were first introduced in telecommunications in 1980, more than 1.5 million households have been connected to the fiber optic network each year in Germany alone and more than 750,000 km of fiber optic cables have already been laid. In addition to the possibility of transmitting at very high data rates (petabit/s), the use of fiber optic transmission in the Internet reduces energy consumption by a factor of around 17 compared to conventional copper cables.

The reason why this technology has not yet been adopted in the automotive industry is likely due to the MOST-Bus (Media Oriented Systems Transport), which was developed in the 1990s. This was mainly used for infotainment applications in vehicles and brought certain limiting factors with it, such as a shared bandwidth and a maximum temperature limit of 85°C. Furthermore, the MOST-Bus was a proprietary solution that rendered the use of alternative protocols impossible.

Since then, however, the industry has made major advances in the field of optical data transmission. Not only have the data rates increased from 150 Mbps (MOST) to 50 Gbps (Ethernet), but the fibers and cable structure have also been optimized, meaning that existing automotive specifications or potential bending radii no longer represent an obstacle for use in vehicles. This technology can also be easily used for transmission over extremely long distances, which makes optical data transmission increasingly interesting for truck-trailer applications.

What improvements have been made in the field of optical data transmission?

A lot has happened regarding the development of optical components in recent years. For example, if you examine the cables, you can see that the optical attenuation has been reduced by a significant percentage, which enables transmission over very long distances. The robustness of the fibers and cables has also been improved to withstand the high demands of the automotive industry. A great deal has been achieved, not only in connection technology, but also in transmission technology, where the systems used can transmit in both directions and control multiple applications with different wavelengths along a single fiber. If you apply this to the automotive industry, it opens up the possibility of already using future-proof technology that meets customer requirements.

Are there any companies investing in optical data transmission for automotive applications?

Global research is required to answer this question because not many companies operating in the automotive environment are addressing this topic. When looking across Europe, it becomes clear that apart from MD ELEKTRONIK, only a few other players have initiated basic projects incorporating this technology. One of these companies has been working for years on the key element of transmission: the transceiver. It is a Spanish start-up company called “KD” that has developed a new process for mounting a transceiver (transmitting and receiving unit) with an integrated circuit (IC) onto a substrate. Combined with the advantages of optical data transmission, this new technology will enable the integration of high-performance Automotive Ethernet links into future vehicle generations.

Consequently, KD has also made a significant contribution to completing the multi-gigabit optical standard IEEE 802.3cz.

Cooperation with ZF

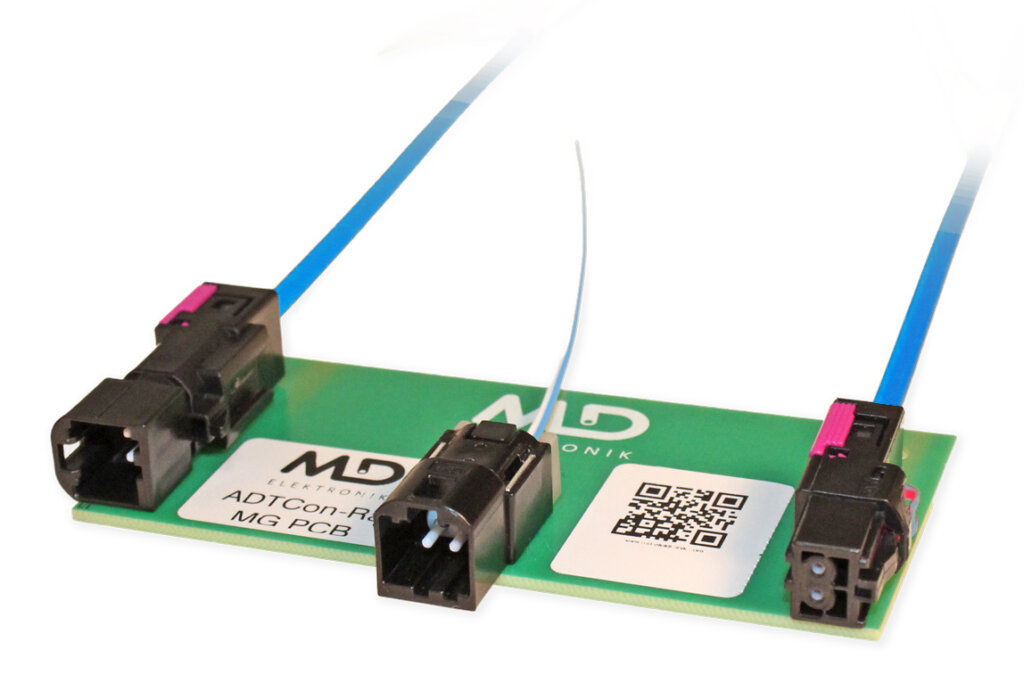

ZF Friedrichshafen and MD ELEKTRONIK have been cooperating since 2024 to implement this idea in a real control unit. Utilizing innovative technology and newly developed connectors, a functional demonstrator based on the ProAI high-performance computer has been successfully realized.

ZF's press releaseWhat are the advantages of using optical data transmission?

When comparing the attenuation (which cannot exceed 35 dB at 11 m) as a critical element of data transmission via copper, it becomes clear that the optical attenuation value (approx. 2.5 dB/km) is very low. In new developments for applications in data centers, this attribute has been further enhanced to now achieve attenuation values of less than 0.1 dB/km. However, there are many other positive aspects in addition to this important advantage. For example, the use of optical fibers can reduce the weight by approximately 66% and the space required by around 10% compared to equivalent copper cable solutions. Moreover, fiber optic cables are less sensitive to temperature and allow EMC-safe data transmission over very long distances, which is particularly useful for truck trailers and buses, for example. And there are many other significant advantages for data transmission, starting with the low transmission losses compared to copper and the total absence of EMC-critical issues such as “crosstalk” in optical transmission. In contrast, an equivalent transmission solution using copper cables requires a high level of shielding. Optical data transmission offers another very useful feature for future applications, namely the option of bidirectional transmission at the same bandwidth.

New developments for automotive applications have already considered the most important aspects such as resistance to mechanical tensile forces and reverse bending stress in the cable structure and connectors, and samples suitable for automotive applications have been distributed to various suppliers and OEMs.